The World Is Running Out of Elements, and Researchers Are Looking in Unlikely Places for Replacements

Make no miscalculation: We are functioning out of features. As human beings have stuffed in all the corners of the periodic desk, each individual factor has resulted in technological innovation.

Europium and indium are vital for televisions and touch screens. Rhenium is essential in fighter jet engines. And to stay away from some of the results of climate modify, we need to have lithium and cobalt for electrical automobile batteries, tellurium for solar panels and dysprosium for wind turbines.

However we cannot make these features — they fashioned, along with Earth, billions of many years ago. To replenish our dwindling shops and hold up with a increasing, modernizing entire world, we should mine for more.

Prospectors are widening their search as they seek new resources of raw supplies that will not disrupt populated parts — no one wishes a mine in their yard. They are hunting for purely natural ores in sites when regarded as well distant to mine, right before the materials’ desire justified the prices and arduous journeys: the Arctic, the deep sea and even the asteroids closest Earth.

But after a century of major industrial action, we also have a wealth of human waste products full of reclaimable features: wastewater, discarded shopper electronics and even pollution in the environment. Technologies that scientists are producing to clean up these wastes can actually convert trash into treasure. “If you’re going to remove it, why not recover it?” claims William Tarpeh, a chemical engineer at Stanford College.

The Arctic

As warmer land and water temperatures melt glaciers and sea ice close to the globe, permafrost also has started out thawing. The modifications to permafrost destabilize existing properties and any long term design in the Arctic. The lack of ice streets on frozen rivers and lakes boundaries travel throughout the Arctic, including in parts that would be likely mining web-sites. (Credit history: Jane Rix/Shutterstock)

The Good White North is by now a acquainted area for mining. The sector has been an economic mainstay of Arctic nations around the world for generations. Finland’s Ojamo iron mine began generation in 1530, though Sweden’s Falun Mine operated as far again as the Viking era. And nonetheless today, mines scattered in the course of Russia’s tundra source some 40 per cent of the world’s palladium, important for catalytic converters and gas cells. But the Arctic’s excessive temperatures and unforgiving landscape have precluded vast swaths from exploitation.

That might quickly modify. “The exploration up in the North is not finished,” claims Janice Zinck, the director of inexperienced mining innovation with the federal agency Normal Methods Canada. “We’re definitely just scratching the surface in terms of what’s out there.”

Renewed fascination in the Arctic has been driven by a shift in desire. Base metals like iron and copper, utilised in bulk for infrastructure, are not the top priority today. Now, the force is on for more so-termed know-how metals, this sort of as the scarce earth features dysprosium and terbium, which bolster magnets and give screens colour.

Arctic nations joined forces from 2012 to 2016 on the Circum-Arctic Mineral Useful resource Undertaking to compile info on the region’s riches. They determined numerous significant deposits, including one of the world’s major web-sites of scarce earth features at Kvanefjeld in Greenland. And as the Arctic Circle warms, more parts like Greenland’s inside and the Arctic Ocean’s seafloor will open up. But the altering climate also raises the challenges, warns Zinck. Thawing permafrost destabilizes existing and long term properties and mining buildings, though the melting of worthwhile ice streets — frozen rivers or paths on frozen lakes — boundaries travel.

Sustainability will be essential for long term Arctic mines, claims Zinck. Mining corporations operating in Norway, for illustration, have been essential given that 2010 to restore the area at the end of a mine’s everyday living. “Rebuilding after extraction need to be an obligation,” claims geologist Morten Smelror, former director of the Geological Survey of Norway.

The Deep Sea

Deep-sea polymetallic nodules (higher than) often comprise nickel, cobalt and copper. Nautilus Minerals intends to use its seafloor generation applications (left) to slice, extract and obtain material in search of seafloor resources. (Credit history: Emma Critchley/Nautilus Minerals)

Jules Verne predicted the existence of worthwhile seafloor minerals only a couple of many years right before their genuine discovery. In Twenty Thousand Leagues Under the Sea, Captain Nemo of the submarine Nautilus claims, “There exist, at the base of the sea, mines of zinc, iron, silver, and gold, the functioning of which would most absolutely be practicable.”

3 many years later, in 1873, the genuine-everyday living English exploration ship HMS Challenger proved Nemo appropriate when it hauled up curious, potato-sized black rocks from the flooring of the Pacific: so-termed polymetallic nodules abundant with manganese, iron, nickel and cobalt, among the other metals. About the next one hundred fifty many years, scientists uncovered two more styles of steel-abundant resources beneath the waves: deposits of seafloor large sulfides, often uncovered at the boundaries of tectonic plates, that have copper, gold and silver and cobalt crusts, which expand on underwater volcanoes scattered around the globe, including a big populace in the Pacific.

With deposits of superior-quality metals dwindling, corporations have begun making strategies to tap these factor-abundant deposits. As a reward, seafloor mining faces fewer of the challenges associated with terrestrial mining. For one, the seafloor is in nobody’s yard, so disturbance to communities is nominal. Oceans also deal with more than 70 per cent of the earth, probably hiding sufficient features to source all of humanity’s requirements for the foreseeable long term. And, most likely most crucially of all, though every nation keeps mineral legal rights inside two hundred nautical miles of its coastline, the seafloor’s features in intercontinental waters really do not belong to any one country.

No deep-sea mining functions are functioning now, but corporations and nations around the world are eager to modify that. Australian enterprise Nautilus Minerals intends to start out professional mining of seafloor large sulfides off the coastline of Papua New Guinea when it untangles by itself from monetary trouble. Diamond Fields Methods is hunting to do the similar off the coastline of Saudi Arabia in the Purple Sea. As for intercontinental waters, all eyes are on the International Seabed Authority to set worldwide deep-sea mining legal guidelines this calendar year, after it finishes assessing the likely environmental effect.

“I’m fairly optimistic about that system, gradual and bureaucratic as it is,” claims biologist Adrian Glover of the Normal Record Museum in London, who is concerned with the International Seabed Authority’s assessment. “It’s been really profitable in an emerging sector and acquiring individuals considering about environmental challenges and legal obligations, effectively right before the sector commences. And which is a definitely beneficial factor.”

The Asteroids

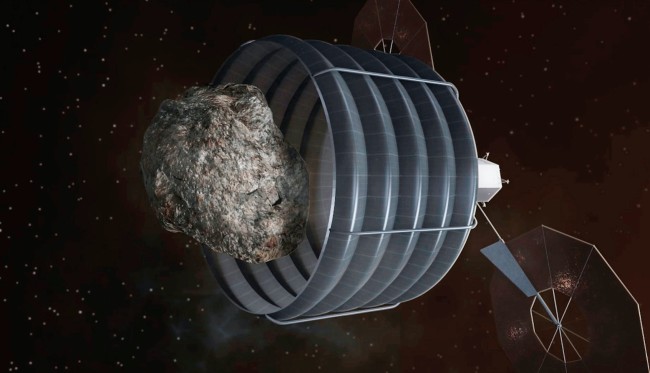

Asteroids might one day be resources for platinum. But initially we’d have to seize one robotically, proven in this artist’s rendering from NASA. (Credit history: NASA)

Just before NASA’s Apollo missions to the moon, our only firsthand understanding of space rocks arrived from the meteorites that had fallen to Earth. Now, not only have we studied moon rocks, but we’ve also collected samples instantly from asteroids and comets. And it turns out space is full of beneficial supplies. Of the around 20,000 identified asteroids closer than Mars, more than seven hundred are metallic, claims Mitch Hunter-Scullion, founder and CEO of Asteroid Mining Company in the U.K.

When in fact mining asteroids would be, ahem, astronomically pricey, one steel by yourself could make it worth the vacation. “The business case is driven by the price tag of platinum,” claims mechanical engineer Amanda Hughes of the College of Liverpool. In terrestrial mines, ore that includes five areas per million of platinum is worth mining. An asteroid about a half-mile vast with at the very least 10 ppm of platinum could convert a revenue, she claims. About 50 asteroids healthy that description, in accordance to Hunter-Scullion’s estimate. (Some meteorites have been uncovered with around 120 ppm of platinum.)

Hunter-Scullion is making a detailed databases of other likely resources that could be uncovered in these platinum-abundant asteroids, including base metals like iron and nickel, as effectively as organic carbon and phosphorus, to more increase mining income. He’s also hoping to find water, which could aid humanity’s growth into space.

Asteroid mining could transpire in two ways: by bringing an asteroid to Earth and extracting its minerals here, or — more possible — by crushing the asteroid in space and returning to Earth with the factor-abundant concentrates. If asteroid mining seems like science fiction, which is for the reason that it nonetheless is. Experts would need to have to figure out, for illustration, how to smash and obtain rocks in zero gravity. They are by now getting the initially steps of this system, hunting for platinum-abundant asteroids — prospecting from around a hundred million miles away.

Liquid Wastes

Researchers in Australia are functioning on working with germs to mine aged tailings storage ponds, this sort of as this one in Queensland, for cobalt. (Credit history: Dominic Brown)

Toxic algal blooms, acidic streams and steel-tainted soils have one factor in widespread: These environmental calamities end result from wastewater which is abundant in minerals and metals. Wastewater has typically occupied the center ground between carrying as well couple of features to be exploited as a useful resource, but as well numerous to be healthy for the atmosphere. That is now altering, thanks to mounting environmental issues and the soaring prices of supplies.

The specific features are as diverse as the possible resources. Human and animal sewage is a excellent resource of nitrogen and phosphorus, important substances in making fertilizer for plant development. Desalination functions — which convert saltwater into harmless consuming water — develop concentrated brines full of beneficial metals that are discarded again into the oceans. And the fourteen billion tons of waste tailings — leftover, steel-made up of sludge from mines — produced every calendar year comprise reclaimable features, including scarce earth metals.

The benefit of prospecting in these wastes is that the features are not trapped inside of rocks. As an alternative, the challenge is one of careful chemical separation of the required from the undesired at a molecular level. To do this, scientists have built what are termed seize agents, molecules and supplies that bind only to the wanted substances. Some have engineered germs to secrete proteins that bind to unique features, for illustration.

This method of dealing with wastewater as a useful resource is by now underway close to the entire world. Water treatment vegetation in North The united states and Europe have proven phosphorus restoration programs to counter harmful algal blooms, with a handful even advertising the reclaimed nutrition as fertilizer. In 2018, scientists in Australia made a material that could extract lithium from desalination brines and fracking wastewater. And geo-environmental scientist Anita Parbhakar-Fox of the College of Queensland is functioning on germs that can mine aged tailings ponds for cobalt, an progressively important factor for electrical automobile batteries.

“It pays to go seem at waste,” she claims.

Stable Wastes

(Credit history: Umicore)

City mining seems extraordinary, but it’s definitely just a glorified term for recycling. It’s an thought that has been close to for millennia, claims industrial ecologist Peter Afiuny, who is government vice president of City Mining Co. in Austin, Texas. Battered and damaged Iron Age weapons ended up melted down and reforged in later ages, medieval Britain designed churches with stone from Roman ruins, and metals like tin and aluminum are recycled in superior quantities today. It’s widespread sense to harvest the scarce components in today’s discarded shopper products, from cellphones to tractors, for the products of tomorrow. And, as a reward, these “ores” are by now in the urban parts exactly where they are most necessary, rather of buried in mines in challenging-to-achieve locations.

The challenge, however, is that these features are definitely spread out. “The [authentic] mine is disseminated around countless numbers and tens of countless numbers of homes,” claims industrial engineer Christian Hagelüken of supplies enterprise Umicore, based mostly in Brussels. Mining all individuals appliances and electronics initially involves accumulating them all into one area.

A 2nd challenge is dismantling today’s exceptionally complex products. Elements now suffuse know-how like spices in an elaborate dish — iPhones, for instance, comprise a dash of indium, a sprinkling of terbium and hints of some 70 other features. Most shopper products ended up under no circumstances built to be simply disassembled and recycled, so minimizing that big pile of products into its substances is difficult.

To that end, corporations have pioneered numerous techniques to improved reclaim the worthwhile areas of our aged tech. City Mining Co. focuses on extracting neodymium-iron-boron magnets from challenging drives, wind turbines and more, turning them into powder and making new magnets instantly from that. And Umicore’s furnaces can melt and individual any of 17 features from aged catalytic converters and circuit boards.

But though this tactic delivers a recycling method to mining, it does pose an inherent conflict with sustainability: Mining obsolete products for supplies only operates if the authentic products have a quick life span to start out with. If our tech applications stay as long as we do — a purpose in any environmentally sound long term — this mine will grow to be progressively scarce.

Gaseous Wastes

Carbon Engineering has opened a pilot plant in British Columbia that captures about a ton of carbon dioxide each individual day. It aims to construct a plant proven in an artist’s rendering, to soak up two.two billion lbs . of CO2 yearly. (Credit history: Carbon Engineering, Ltd.)

It might sound futuristic (or preposterous) to extract resources from the air, but we’ve properly been executing it given that 1913. The Haber-Bosch system converts atmospheric nitrogen into ammonia, which is utilised for fertilizers and explosives. Today, scientists want to reclaim a unique factor that humanity has been shifting into the environment for around a century, one with far higher stakes: carbon.

Humans have been releasing the carbon buried in fossil fuels in the kind of carbon dioxide, with disastrous results. Anthropogenic climate modify is connected to melting ice sheets and mounting seas that are predicted to flood coastal metropolitan areas and island nations. More powerful storms and droughts have grow to be the norm. The U.N.’s 2018 Intergovernmental Panel on Local climate Modify report concluded that producing carbon-seize systems is now a necessity if we’re to stave off the worst results of climate modify.

But it’s not uncomplicated. One of the most significant challenges is that, even nevertheless carbon dioxide stages are superior, the fuel nonetheless can make up just .04 per cent of the environment. To attract this tiny sum of carbon from the air properly, the startup enterprise Carbon Engineering in Squamish, British Columbia, designed a gadget that forces air into make contact with with an alkaline option that absorbs carbon dioxide. Within the gadget, the alkaline option flows downward, guided by ridged plastic surfaces, like corrugated cardboard, nestled upright. The option coats individuals surfaces, building a vast area of make contact with with air as it streams by means of the gadget horizontally, encouraging it grab individuals minute quantities of carbon in the air.

At present, Carbon Engineering’s pilot plant captures about a ton of carbon dioxide per day, and the enterprise is scheduling a full-scale plant that would soak up a million metric tons (or just around two.two billion lbs .) of CO2 yearly.

But compared with the carbon in fossil fuels, which will come packed with energy thanks to the hydrogen atoms it carries, carbon dioxide is rather inert. So for mined carbon to be repurposed again into gas, energy requirements to be injected (in the kind of new hydrogen atoms) again into the carbon. Iceland-based mostly Carbon Recycling International and other people have produced big strides in this area, turning CO2 emissions from power vegetation into fuels like liquid methanol.

Carbon Engineering’s tactic is to cobble together proven chemical processes to initially lower carbon dioxide to carbon monoxide, and then change that into a mild artificial crude oil.

Ultimately, we could be in a position to pull our fuels actually out of slim air.

Rapid Info

-

The Arctic Circle is defined as the area exactly where the sunlight can glow continuously for 24 hrs. But for the reason that Earth’s axial tilt is altering, the Arctic Circle is shifting north just about 50 feet each individual calendar year. For usefulness, most geologists realize the area north of sixty levels latitude as the Arctic.

-

Even nevertheless it is dilute, seawater includes major steel resources. Beginning in the nineteen seventies, Japanese scientists attempted to mine uranium from seawater by producing remarkably absorbent sponges, but they weren’t efficient sufficient to acquire to industry.

-

A lot of metals are termed hitchhikers for the reason that they are byproducts of other metals’ generation. Some examples contain cobalt, indium, tellurium and dysprosium the only way to mine them is to purify them in the course of the refinement of other features.

-

One of the most effectively-identified examples of extracting resources from the air, the Haber-Bosch system for converting nitrogen to ammonia, developed artificial fertilizers and profitable crops, thereby fueling a worldwide populace to around 7.five billion today. On the other hand, on the flip side, it is responsible for 1.4 per cent of worldwide carbon emissions.

— X.L.