Battery makers have for yrs been trying to switch the graphite anode in lithium-ion batteries with a edition built of silicon, which would give electric vehicles a significantly longer array. Some batteries with silicon anodes are receiving shut to industry for wearables and electronics. The recipes for these silicon-abundant anodes that a handful of corporations are building usually use silicon oxide or a mix of silicon and carbon.

But Irvine, CA-centered Enevate is applying an engineered porous film built mostly of pure silicon. In addition to becoming economical, the new anode material, which founder and chief engineering officer Benjamin Park has spent additional than ten yrs building, will lead to an electrical auto (EV) that has thirty percent additional array on a single cost than today’s EVs. What’s additional, the battery Enevate envisions could be charged up enough in five minutes to provide 400 km of driving array.

Major names in the battery and automotive business are listening. Carmakers Renault, Nissan, and Mitsubishi, as well as battery-makers LG Chem and Samsung, are buyers. And lithium battery pioneer and 2019 Chemistry Nobel Prize winner John Goodenough is on the company’s Advisory Board.

When lithium-ion batteries are charged, lithium ions transfer from the cathode to the anode. The additional ions the anode can maintain, the increased its vitality capability, and the longer the battery can run. Silicon can in concept maintain 10 occasions the vitality of graphite. But it also expands and contracts radically, slipping aside just after a several cost cycles.

To get all around that, battery makers this sort of as Tesla right now increase just a very small bit of silicon to graphite powder. The powder is mixed with a glue-like plastic known as a binder and is coated on a skinny copper foil to make the anode. But, suggests Park, lithium ions respond with silicon initial, just before graphite. “The silicon continue to expands quite a bit, and that plastic binder is weak,” he suggests, explaining that the complete electrode is additional probably to degrade as the quantity of silicon is ramped up.

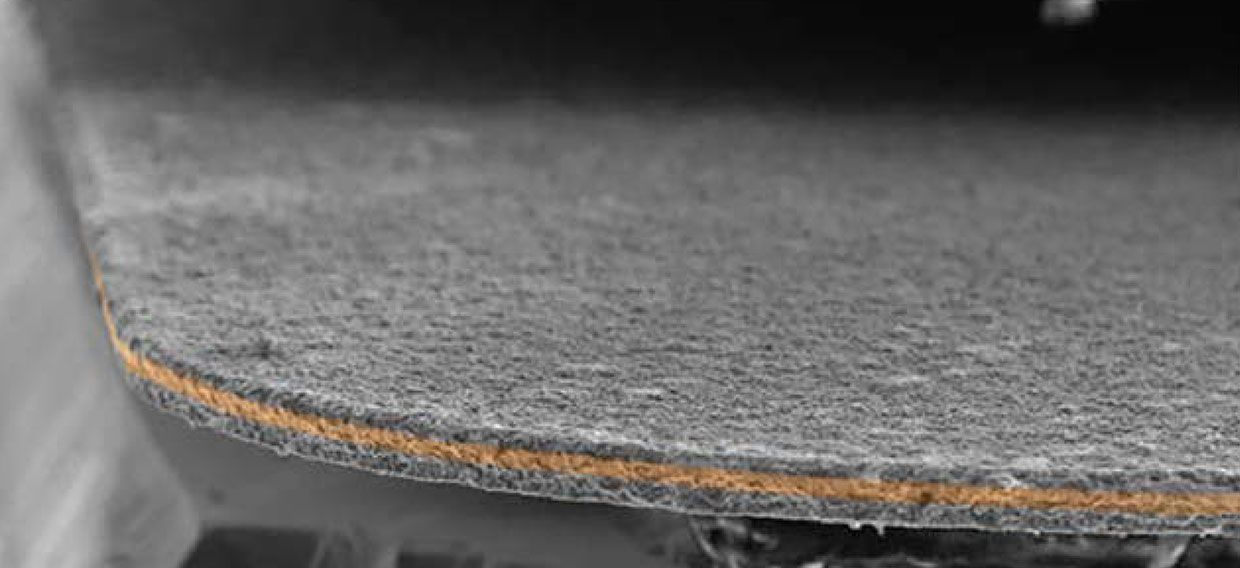

Enevate does not use plastic binders. Alternatively, its patented process generates the porous ten- to 60-µm-thick silicon film right on a copper foil. The cherry on top rated is a nanometers-thick protective coating, which, suggests Park, “prevents the silicon from reacting with the electrolyte.” That type of reaction can also hurt a battery.

The process does not need high-top quality silicon, so anodes of this type cost less than their graphite counterparts of the very same capability. And due to the fact the material is mainly silicon, lithium ions can slip in and out very rapidly, charging the battery to seventy five percent of its capability in five minutes, with no leading to significantly enlargement. Park likens it to a high-capability motion picture theater. “If you have a comprehensive motion picture theater it usually takes a extended time to discover the one vacant seat. We have a theater with 10 occasions additional capability. Even if we fill that theater halfway, [it continue to does not take extended] to discover vacant seats.”

The company’s roll-to-roll processing methods can make silicon anodes rapidly more than enough for high-volume production, suggests Park. By coupling the silicon anode with conventional cathode resources this sort of as nickel-manganese-cobalt, they have built battery cells with vitality densities as high as 350 watt-hours for every kilogram, which is about thirty percent additional than the specific vitality of today’s lithium-ion batteries. Enevate suggests it is now working with many big automotive corporations to build common-size battery cells for 2024-25 model 12 months EVs.