A little soon after 8:00 p.m. on April 19, 2019, a captain with the Peoria, Arizona, hearth department’s Hazmat device, opened the doorway of a container stuffed with much more than 10,000 energized lithium-ion battery cells, part of a utility-scale storage procedure that had been deployed two several years before by the regional utility, Arizona General public Services.

Previously that evening, at close to 5:forty one p.m., dispatchers had acquired a call alerting them to smoke and a “bad smell” in the location close to the McMicken Battery Strength Storage System (BESS) web page in suburban Phoenix.

Sirens blaring, three hearth engines arrived at the scene in 10 minutes. Shortly soon after their arrival, to start with responders realized that energized batteries have been associated and elevated the call to a Hazmat reaction. Soon after consulting with utility personnel and determining on a system of motion, a hearth captain and three firefighters approached the container doorway shortly prior to 8:00 p.m., planning to open up it. The captain, discovered in a later on investigation as “Captain E193,” opened the doorway and stepped inside. The other three stood nearby.

The BESS was housed in a container arranged to keep 36 vertical racks divided into two rows on both side of a three-ft-large hallway. Twenty-7 racks held 14 battery modules produced by LG Chem, an eighty kW inverter produced by Parker, an AES Advancion node controller employed for facts assortment and interaction, and a Battery Safety Unit (BPU) produced by LG Chem.

The battery modules in turn contained 28 lithium-ion battery cells of Nickel Manganese Cobalt (NMC) chemistry. These modules have been linked in series, providing a for every-rack nominal voltage of 721 V. The overall procedure had a nameplate potential to provide 2 MW of energy above one hour for a lifetime electrical power ranking of 2 MWh. With 27 entire racks, there have been 10,584 cells in the container. Soon after a entire day of charging, the batteries have been close to ninety p.c of potential.

With the doorway to the BESS container open up and Captain E193 at its threshold, combustible gases that had created up inside considering the fact that the incident started quite a few several hours prior to acquired a breath of oxygen and observed an ignition supply.

The gases erupted in what was described as a “deflagration occasion.” Firefighters just outside the house of the incident sizzling zone said they read a loud sounds and saw a “jet of flame” lengthen some 75 ft out and 20 ft up from the doorway.

In the explosion, Captain E193 and firefighter E193 have been thrown from and under a chain-backlink fence surrounding the facility. The captain landed much more than 70 toes from the open up doorway the firefighter landed thirty ft away.

The captain’s accidents incorporated a traumatic mind injuries, an eye injuries, backbone destruction, broken ribs, a broken scapula, thermal and chemical burns, inside bleeding, two broken ankles, and a broken foot.

The firefighter experienced a traumatic mind injuries, a collapsed lung, broken ribs, a broken leg, a divided shoulder, laceration of the liver, thermal and chemical burns, a missing tooth, and facial lacerations.

The timeline and series of situations is not usually disputed. However, a dispute has erupted in modern weeks above what particularly transpired inside the BESS container at close to four:54 p.m. that initiated a thermal runaway that cascaded across multiple battery cells.

In a report introduced in late July, the utility and its third-occasion investigator, DNV-GL, said that their assessment of the proof pointed to the failure of a single lithium-ion cell as triggering the situations.

In a separate, preliminary report filed times later on with state officers, LG Chem, which equipped the li-ion batteries, challenged that acquiring. The South Korea-primarily based battery supplier said the APS report missed a quantity of particulars about the accident. Those particulars, LG Chem told regulators, indicated that the cell thermal runaway started because of to “intense heating” brought about by a heat supply “such as exterior electrical arcing” on one of the battery racks.

Scott Bordenkircher, who served as APS’ Director of Technological innovation Innovation & Integration at the time of the accident, said in an job interview that the utility accepts the findings of its third-occasion accident investigation, which was finished by Davion Hill, Ph.D., the U.S. Strength Storage Chief for DNV GL. “We have self-assurance in our third-occasion investigator,” Bordenkircher said.

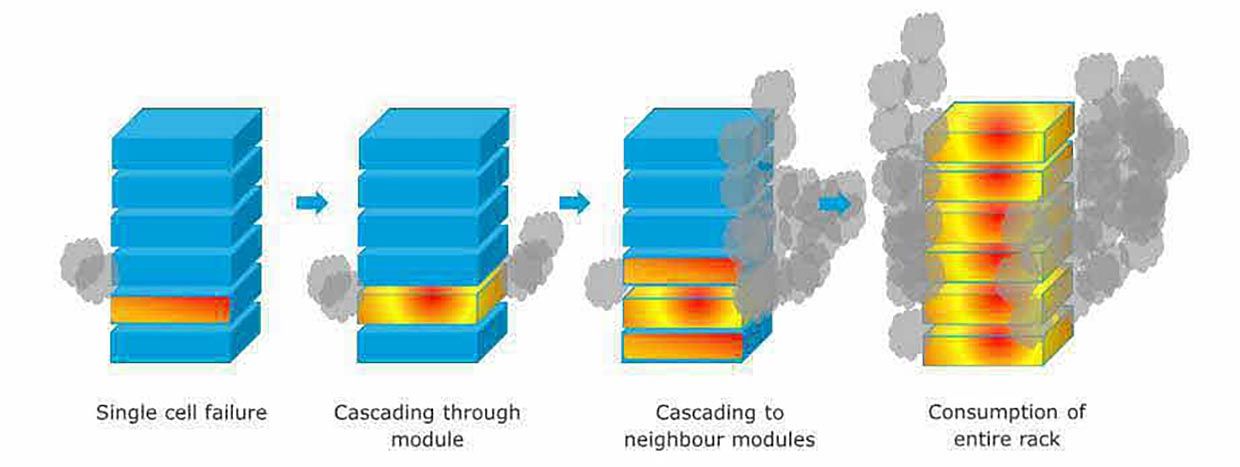

In its 78-page report [PDF], DNV GL said that what was to start with assumed to be a hearth was in point an substantial cascading thermal runaway occasion in the BESS. That occasion was initiated by an inside cell failure in one battery cell, discovered as cell seven-2 on Rack fifteen. The failure was brought about by “abnormal lithium metallic deposition and dendritic growth” in the cell, the report said.

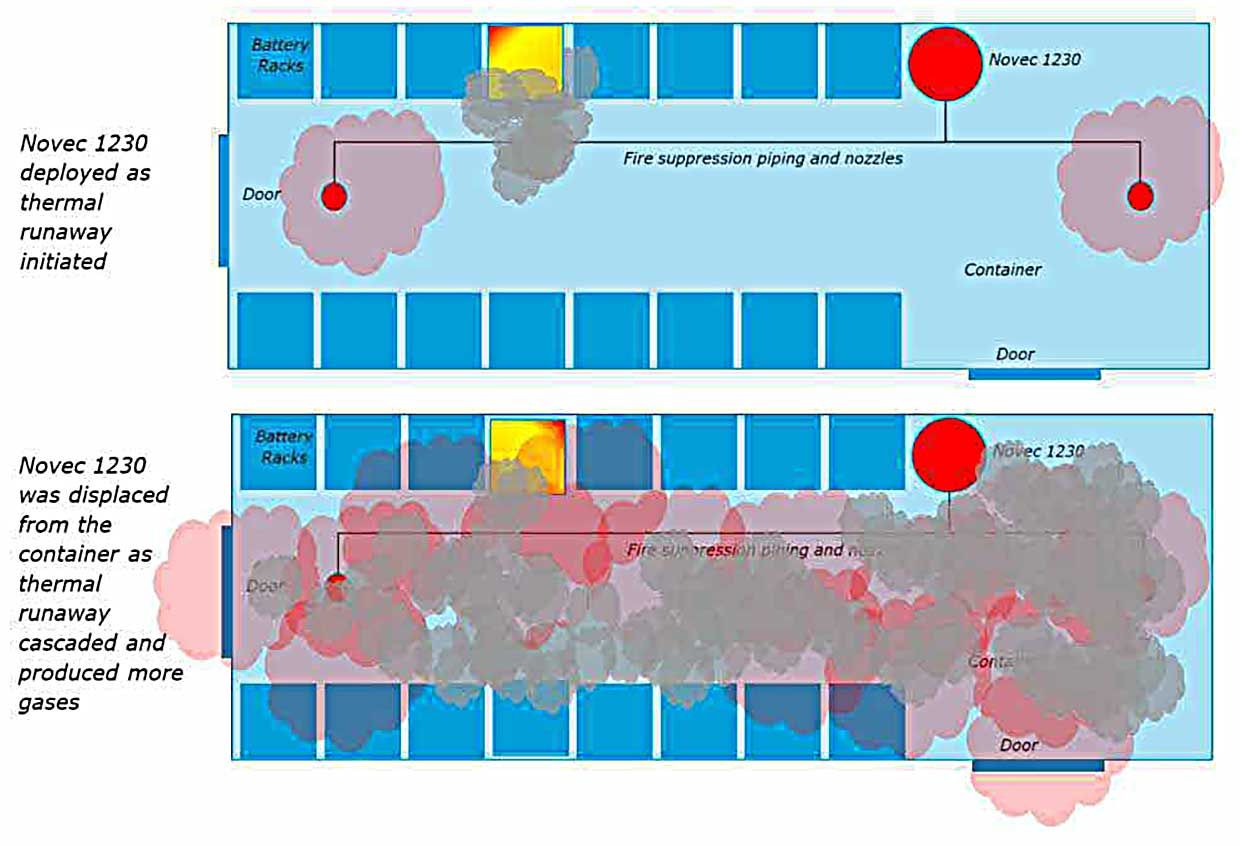

Once the failure happened, thermal runaway cascaded from cell seven-2 through each individual other cell and module in Rack fifteen via heat transfer. The runaway was aided by the “absence of satisfactory thermal barrier protections” amongst battery cells, which otherwise may have stopped or slowed the thermal runaway.

As the occasion progressed, a significant volume of flammable fuel was made in the BESS. Missing ventilation to the outside the house, the gases created a flammable ambiance in the container. All-around three several hours soon after thermal runaway started, when firefighters opened the BESS doorway, flammable gases manufactured get hold of with a heat supply or spark and exploded.

It was a “tragic incident,” Bordenkircher said.

It also was not the to start with time that a lithium-ion battery had unsuccessful.

The APS report listed situations achieving back to 2006 that associated thermal runaway situations in lithium-ion batteries. In one widely report incident in January 2013, a Boeing 787-8 seasoned smoke and heat coming from its lithium-ion battery-primarily based auxiliary energy device. It was later on determined that the failure was brought about by an inside cell defect, which was exacerbated as thermal runaway cascaded through all the cells in the battery pack, releasing flammable electrolyte and gases.

“The point out of the sector is that inside defects in battery cells is a recognized concern,” said Hill. Even so, troubles with the technology have not been properly communicated amongst, say, the personalized electronics sector and the automotive sector or the aerospace sector and the electrical power sector.

“Overall, across the sector there was a hole in knowledge,” Bordenkircher said. The technology moved ahead so quickly, he said, that specifications and knowledge sharing had not kept up.

The McMicken BESS accident also was not the to start with for APS. In November 2012, a hearth ruined the Scale Strength Storage Method (ESS) at an electrical substation in Flagstaff in northern Arizona. The ESS was produced by Electrovaya and consisted of a container housing 16 cabinets made up of 24 lithium-ion cells.

An investigation into that accident determined that a seriously discharged cell degraded and afflicted a neighboring cell, touching off a hearth. The root trigger of the 2012 accident was observed to be faulty logic employed to regulate the procedure.

The regulate logic had been updated much more than two dozen instances all through the eleven months that the BESS operated. But quite a few missed options could have prevented the hearth that ruined the device, the accident report said. It pointed in unique to an occasion the former May in which a cell was “severely discharged” even as the logic was “continuously charging the cell from the supposed design.” Soon after the May occasion, the logic was not adjusted to handle that improper conduct.

An APS spokesperson said that lessons realized from this 2012 incident have been included into the design and operation of the McMicken BESS.

In its 162-page rebuttal [PDF] of the McMicken accident LG Chem refuted the utility’s acquiring of fault with its battery.

The battery supplier said that primarily based on accessible proof, “metallic lithium plating did not trigger an inside cell failure main to the initial thermal runaway event” at the McMicken BESS facility. Rather, cell thermal runaway started through rigorous heating of the afflicted cells brought about by an exterior heat supply, this kind of as exterior electrical arcing on Rack fifteen.

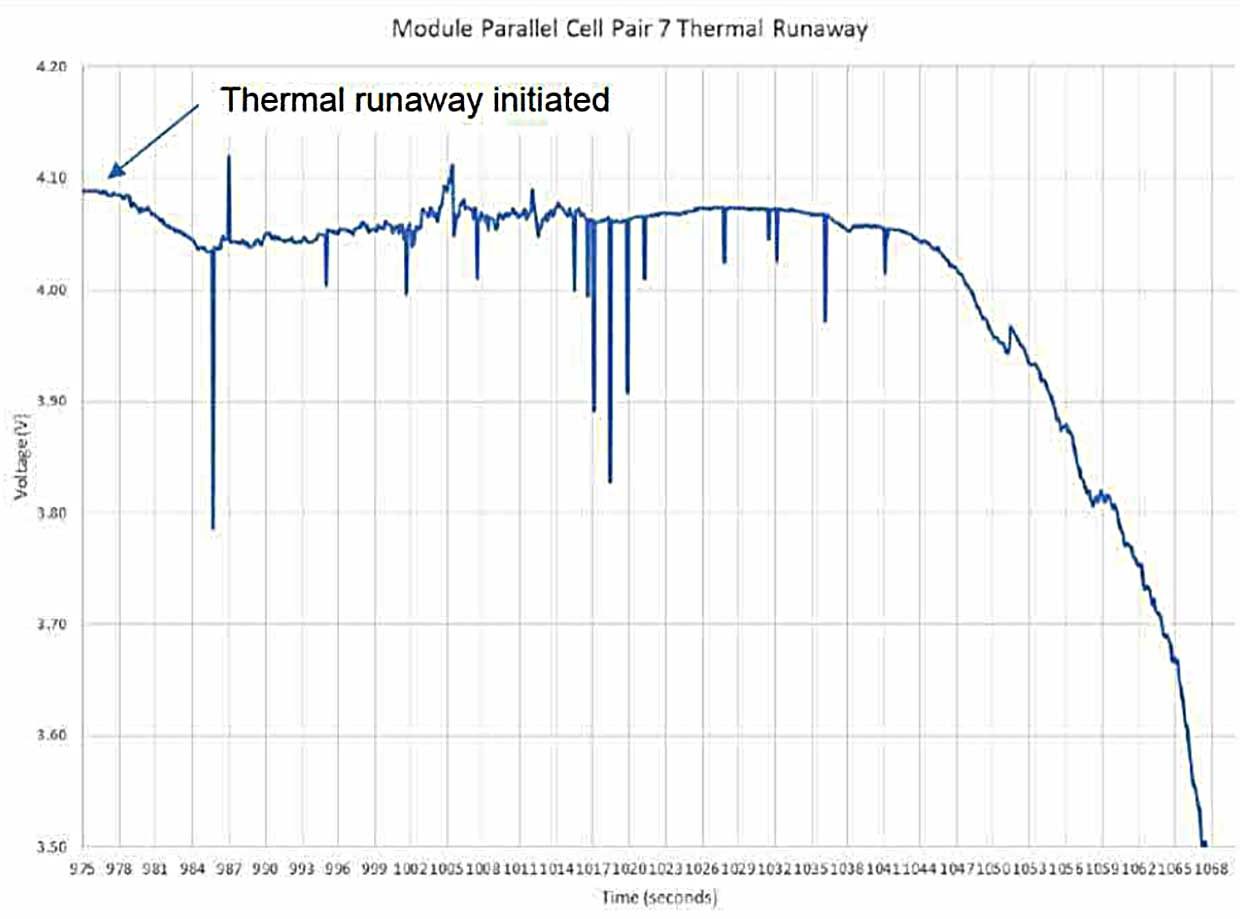

LG Chem said that its possess third-occasion investigator, Exponent Inc., analyzed the inside cell failure idea. It did so by forcing a parallel cell configuration into thermal runaway. It then compared the ensuing voltage profile to the voltage profile recorded all through the incident. It observed that the two did not match, main to the conclusion that the explosion’s trigger was not likely to have been “an inside short in a single cell.”

The battery maker also said that facts recorded all through the incident confirmed a discharging recent of four.9A (amps) present all through the voltage excursion. It said that though the APS report acknowledged that the recent flipped from -27.9A charging to four.nine A discharging,“it offered no rationalization for the occasion.” To LG Chem, on the other hand, the point that the discharging recent was at four.9A, in its place of zero, “means the recent without a doubt flowed to somewhere else,” supporting what it said was a probable double-stage electrical isolation failure and not an inside cell short.

(Complicating the write-up-accident investigation was the point that the hearth ruined procedure regulate electronics in the container. That still left dozens of battery modules energized with no way to discharge them. It took 7 weeks for the utility to figure out a system to eliminate the modules one by one and bleed off their stored electrical power.)

The reports and their divergent conclusions signal the start out of competing interpretations of accessible facts as the utility and its battery supplier operate to locate a single trigger for the accident.

“We don’t want a general public argument about it,” said DNV GL’s Davion Hill. For him, the most important stage is that “we had a cascading thermal runaway that led to an explosive atmosphere” at the APS McMicken BESS. The purpose now need to be to make storage methods safer through specifications advancement and details sharing.

Soon after the accident, APS placed a keep on BESS deployment across its assistance territory. The technology is viewed as essential to conference the utility’s announced plans to deliver one hundred p.c “clean energy” by 2050. Two other BESS methods that had been running at the time of the April 2019 accident have been taken offline they will keep on being idle until finally retrofits can be built and installed.