“Hydrogen is a pretty fantastic provider for this form of do the job,” says Wei Wang, who is the main scientist for stationary electricity storage study at the Pacific Northwest Countrywide Laboratory in Washington. It is an productive electricity provider, and can be simply saved in pressurized tanks. When needed, the gas can then be transformed again into electrical electricity via a gasoline cell and fed into the grid.

But drinking water electrolyzers are high-priced. They do the job underneath acidic circumstances which have to have corrosion-resistant steel plates and catalysts designed from cherished metals such as titanium, platinum, and iridium. “Also, the oxygen electrode isn’t pretty productive,” says Kathy Ayers, vice-president of R&D at Nel Hydrogen, an Oslo-based mostly organization that specializes in hydrogen generation and storage. “You get rid of about .3 volts just from the point that you are making an attempt to transform drinking water to oxygen or vice versa,” she says. Splitting a drinking water molecule needs an utilized voltage of 1.23 V.

In a bid to conquer this issue, Nel Hydrogen and Wang’s staff at Pacific Northwest joined forces in 2016, soon after receiving funding from the U.S. Office of Energy’s Sophisticated Investigation Jobs Company-Strength. The option they’ve appear up with is a gasoline cell that functions as both equally a battery and hydrogen generator.

“We simply call it a redox-flow cell due to the fact it is a hybrid involving a redox-flow battery and a drinking water electrolyzer,” clarifies Wang.

A redox-flow battery, in essence a reversible gasoline cell, is typically designed up of a favourable and adverse electrolyte saved in two independent tanks. When the liquids are pumped into the battery cell stack situated involving the tanks, a redox reaction occurs, and generates electrical energy at the battery’s electrodes.

By comparison, the new invention has only a single electrolyte, comprised of an iron salt (somewhat than the extra normally applied vanadium) dissolved in acid. When hydrogen ions react with the iron salt (Fe2+), hydrogen gas is generated at the platinum-coated carbon cathode in the battery stack.

“We introduce iron as a intermediary, so we can independent electrolysis into two reactions,” says Wang. Performing so allows a single to regulate wherever and when to reverse the reaction to make electrical electricity to supply to the grid. “The technique gives you overall flexibility… you could do the regeneration all through night time when electrical energy price ranges are at a peak,” he says.

Regenerating Fe2+ in the reverse reaction also allows for the continuous generation of hydrogen gas, he says. “And due to the fact the hydrogen-iron cell makes use of about 50 percent the voltage of a standard electrolyzer, you can make hydrogen at a significantly less expensive value if you do every little thing ideal.”

It also can help that iron is significantly less expensive and extra considerable compared with vanadium.

Qing Wang, a supplies scientist at the Countrywide College of Singapore, sees one more advantage. “If you care extra about purity and want to have ultra-pure hydrogen, then perhaps it is a fantastic option,” he says. Cross-contamination can sometimes occur all through electrolysis due to the fact the hydrogen and oxygen gases generated are so modest that they are ready to traverse the membrane separator.

The new redox-flow cell carried out perfectly in lab assessments, exhibiting a charge ability of up to a single ampere for every sq. centimeter, a 10-fold boost above normal flow batteries. It was also ready to stand up to “several hundred cycles” of charging, which has under no circumstances been demonstrated before in hydrogen ion flow batteries, says Wang, who has a quantity of patents for the invention, with a several extra pending.

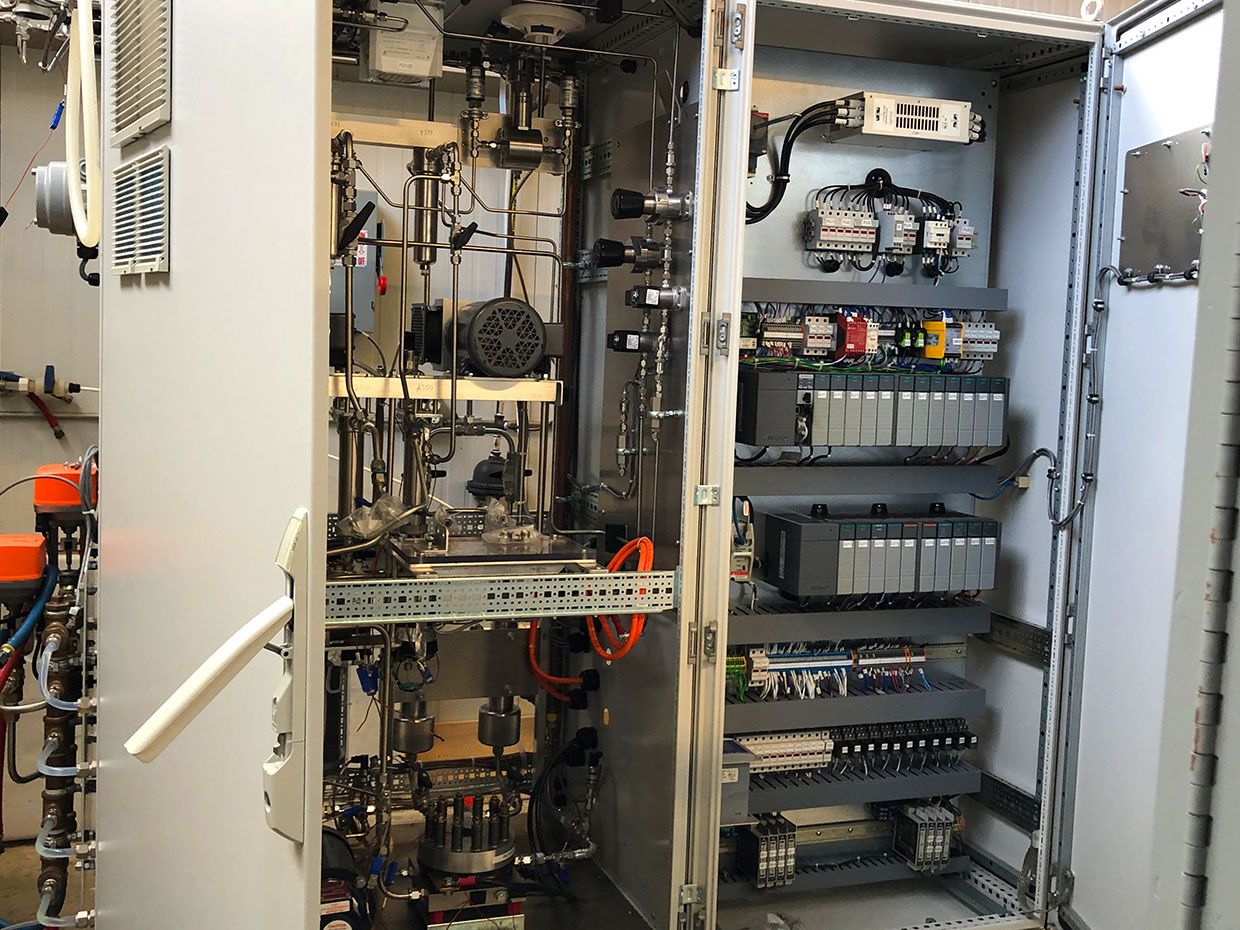

When the PNNL staff experimented on a one cell measuring ten sq. centimeters, Ayers and her colleagues at Nel Hydrogen proved that the technology could do the job even when scaled up to a 5-cell stack measuring a hundred sq. centimeters. They system to invest the upcoming several months fine-tuning the technique and eradicating kinks, such as how to lessen harm to the pumps brought on by the acidic electrolyte, before commercializing it.

This put up was up to date on twenty April 2020.