We are in a new era of spaceflight: The countrywide area companies are no lengthier the only video game in city, and area is turning out to be much more available. Rockets designed by industrial gamers like

Blue Origin are now bringing personal citizens into orbit. That claimed, Blue Origin, SpaceX, and Virgin Galactic are all backed by billionaires with tremendous assets, and they have all expressed intentions to promote flights for hundreds of 1000’s to millions of dollars. Copenhagen Suborbitals has a incredibly distinct eyesight. We believe that spaceflight really should be accessible to any one who’s ready to place in the time and effort and hard work.

Copenhagen Suborbitals was established in 2008 by a self-taught engineer and a area architect who had beforehand worked for NASA. From the starting, the mission was distinct: crewed spaceflight. Both founders still left the organization in 2014, but by then the venture had about fifty volunteers and a great deal of momentum.

The group took as its founding basic principle that the difficulties included in setting up a crewed spacecraft on the low-priced are all engineering issues that can be solved, just one at a time, by a diligent workforce of good and committed men and women. When men and women talk to me why we’re executing this, I at times response, “Simply because we can.”

Volunteers use a tank of argon fuel [still left] to fill a tube inside which engine things are fused jointly. The workforce not too long ago produced a gasoline tank for the Spica rocket [ideal] in their workshop.

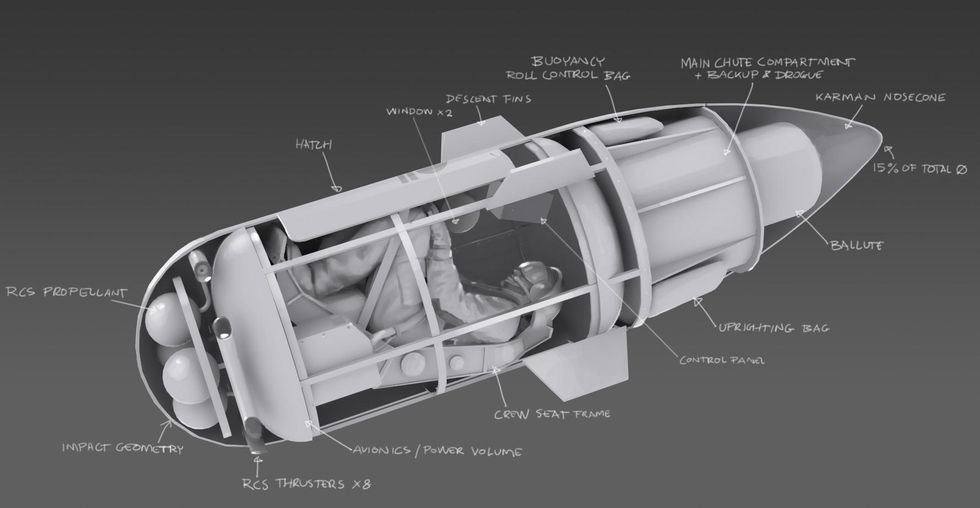

Our objective is to access the Kármán line, which defines the boundary in between Earth’s environment and outer area, one hundred kilometers over sea amount. The astronaut who reaches that altitude will have various minutes of silence and weightlessness after the engines cut off and will love a breathtaking perspective. But it will never be an easy ride. Through the descent, the capsule will practical experience exterior temperatures of 400 °C and g-forces of three.5 as it hurtles through the air at speeds of up to three,five hundred kilometers for each hour.

I joined the group in 2011, after the organization had previously moved from a maker area inside a decommissioned ferry to a hangar close to the Copenhagen waterfront. Before that 12 months, I had viewed Copenhagen Suborbital’s very first launch, in which the Heat-1X rocket took off from a mobile launch system in the Baltic Sea—but regrettably crash-landed in the ocean when most of its parachutes failed to deploy. I brought to the organization some fundamental expertise of athletics parachutes attained through my yrs of skydiving, which I hoped would translate into handy skills.

The team’s following milestone came in 2013, when we efficiently released the Sapphire rocket, our very first rocket to consist of guidance and navigation devices. Its navigation laptop used a three-axis accelerometer and a three-axis gyroscope to keep track of its area, and its thrust-handle system saved the rocket on the correct trajectory by relocating four servo-mounted copper jet vanes that were inserted into the exhaust assembly.

We believe that spaceflight really should be accessible to any one who’s ready to place in the time and effort and hard work.

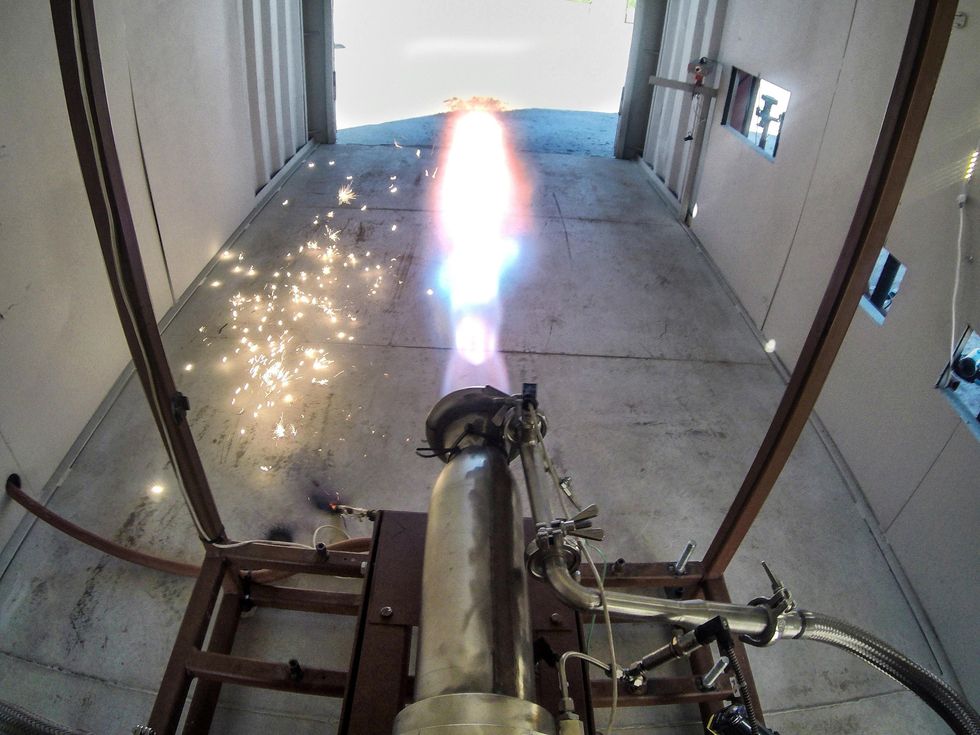

The Heat-1X and the Sapphire rockets were fueled with a mixture of stable polyurethane and liquid oxygen. We were keen to establish a bipropellant rocket engine that combined liquid ethanol and liquid oxygen, for the reason that these types of liquid-propellant engines are both equally economical and highly effective. The Heat-2X rocket, scheduled to launch in late 2014, was meant to demonstrate that technologies. Unfortunately, its engine went up in flames, virtually, in a static examination firing some months before the scheduled launch. That examination was intended to be a managed ninety-second burn up as an alternative, for the reason that of a welding error, much of the ethanol gushed into the combustion chamber in just a handful of seconds, ensuing in a enormous conflagration. I was standing a handful of hundred meters absent, and even from that length I felt the heat on my confront.

The Heat-2X rocket’s engine was rendered inoperable, and the mission was canceled. Even though it was a important disappointment, we uncovered some beneficial classes. Until finally then, we might been basing our types on our existing capabilities—the equipment in our workshop and the men and women on the venture. The failure forced us to take a move back again and think about what new technologies and skills we would need to master to access our stop objective. That rethinking led us to style the reasonably little Nexø I and Nexø II rockets to demonstrate key technologies these types of as the parachute system, the bipropellant engine, and the tension regulation assembly for the tanks.

For the Nexø II launch in August 2018, our launch site was 30 km east of Bornholm, Denmark’s easternmost island, in a part of the Baltic Sea used by the Danish navy for armed service physical exercises. We still left Bornholm’s Nexø harbor at 1 a.m. to access the designated patch of ocean in time for a nine a.m. launch, the time accredited by Swedish air website traffic handle. (Even though our boats were in intercontinental waters, Sweden has oversight of the airspace over that part of the Baltic Sea.) Numerous of our crew associates had used the full preceding working day screening the rocket’s a variety of devices and bought no sleep before the launch. We were jogging on coffee.

When the Nexø II blasted off, separating neatly from the launch tower, we all cheered. The rocket continued on its trajectory, jettisoning its nose cone when it arrived at its apogee of 6,five hundred meters, and sending telemetry information back again to our mission handle ship all the even though. As it started to descend, it very first deployed its ballute, a balloon-like parachute used to stabilize spacecraft at significant altitudes, and then deployed its primary parachute, which brought it gently down to the ocean waves.

In 2018, the Nexø II rocket released efficiently [still left] and returned properly to the Baltic Sea [ideal].

The launch brought us just one move closer to mastering the logistics of launching and landing at sea. For this launch, we were also screening our potential to predict the rocket’s path. I created a product that believed a splashdown 4.two km east of the launch system it truly landed 4. km to the east. This managed h2o landing—our very first less than a thoroughly inflated parachute—was an crucial proof of idea for us, given that a gentle landing is an complete crucial for any crewed mission.

This previous April, the workforce examined its new gasoline injectors in a static engine examination. Carsten Olsen

The Nexø II’s engine, which we identified as the BPM5, was just one of the handful of elements we hadn’t machined totally in our workshop a Danish business manufactured the most intricate engine elements. But when individuals elements arrived in our workshop shortly before the launch date, we realized that the exhaust nozzle was a small little bit misshapen. We failed to have time to purchase a new part, so just one of our volunteers, Jacob Larsen, used a sledgehammer to pound it into shape. The engine failed to glance pretty—we nicknamed it the Franken-Engine—but it worked. Considering that the Nexø II’s flight, we’ve examination-fired that engine much more than 30 moments, at times pushing it past its style boundaries, but we haven’t killed it yet.

The Spica astronaut’s 15-minute ride to the stars will be the item of much more than two a long time of do the job.

That mission also shown our new dynamic tension regulation (DPR) system, which helped us handle the stream of gasoline into the combustion chamber. The Nexø I had used a easier system identified as tension blowdown, in which the gasoline tanks were just one-third filled with pressurized fuel to drive the liquid gasoline into the chamber. With DPR, the tanks are filled to capacity with gasoline and linked by a established of handle valves to a individual tank of helium fuel less than significant tension. That set up allows us regulate the quantity of helium fuel flowing into the tanks to press gasoline into the combustion chamber, enabling us to plan in distinct amounts of thrust at distinct points through the rocket’s flight.

The 2018 Nexø II mission proved that our style and technologies were essentially seem. It was time to start off doing work on the human-rated

Spica rocket.

Copenhagen Suborbitals hopes to mail an astronaut aloft in its Spica rocket in about a 10 years. Caspar Stanley

With its crew capsule, the Spica rocket will evaluate thirteen meters significant and will have a gross liftoff pounds of 4,000 kilograms, of which two,600 kg will be gasoline. It will be, by a important margin, the premier rocket ever designed by amateurs.

The Spica rocket will use the BPM100 engine, which the workforce is at this time production. Thomas Pedersen

Its engine, the one hundred-kN

BPM100, makes use of technologies we mastered for the BPM5, with a handful of enhancements. Like the prior style, it makes use of regenerative cooling in which some of the propellant passes through channels close to the combustion chamber to limit the engine’s temperature. To press gasoline into the chamber, it makes use of a mixture of the very simple tension blowdown approach in the very first section of flight and the DPR system, which provides us finer handle more than the rocket’s thrust. The engine elements will be stainless steel, and we hope to make most of them ourselves out of rolled sheet steel. The trickiest part, the double-curved “throat” section that connects the combustion chamber to the exhaust nozzle, calls for laptop-managed machining devices that we will not have. Luckily for us, we have good market contacts who can assistance out.

A person important alter was the change from the Nexø II’s showerhead-type gasoline injector to a coaxial-swirl gasoline injector. The showerhead injector had about 200 incredibly little gasoline channels. It was tricky to manufacture, for the reason that if anything went erroneous when we were making just one of individuals channels—say, the drill bought stuck—we had to throw the whole factor absent. In a coaxial-swirl injector, the liquid fuels arrive into the chamber as two rotating liquid sheets, and as the sheets collide, they’re atomized to make a propellant that combusts. Our swirl injector makes use of about a hundred and fifty swirler things, which are assembled into just one framework. This modular style really should be less complicated to manufacture and examination for excellent assurance.

The BPM100 engine will change an old showerhead-type gasoline injector [ideal] with a coaxial-swirl injector [still left], which will be less complicated to manufacture.Thomas Pedersen

In April of this 12 months, we ran static tests of various types of injectors. We very first did a demo with a properly-comprehended showerhead injector to set up a baseline, then examined brass swirl injectors manufactured by traditional machine milling as properly as steel swirl injectors manufactured by 3D printing. We were pleased in general with the effectiveness of both equally swirl injectors, and we’re still analyzing the information to ascertain which functioned better. Even so, we did see some

combustion instability—namely, some oscillation in the flames in between the injector and the engine’s throat, a possibly harmful phenomenon. We have a good notion of the bring about of these oscillations, and we’re assured that a handful of style tweaks can remedy the difficulty.

Volunteer Jacob Larsen holds a brass gasoline injector that done properly in a 2021 engine examination.Carsten Olsen

We are going to quickly begin setting up a total-scale BPM100 engine, which will in the end include a new guidance system for the rocket. Our prior rockets, inside their engines’ exhaust nozzles, had steel vanes that we would go to alter the angle of thrust. But individuals vanes generated drag inside the exhaust stream and reduced efficient thrust by about 10 per cent. The new style has

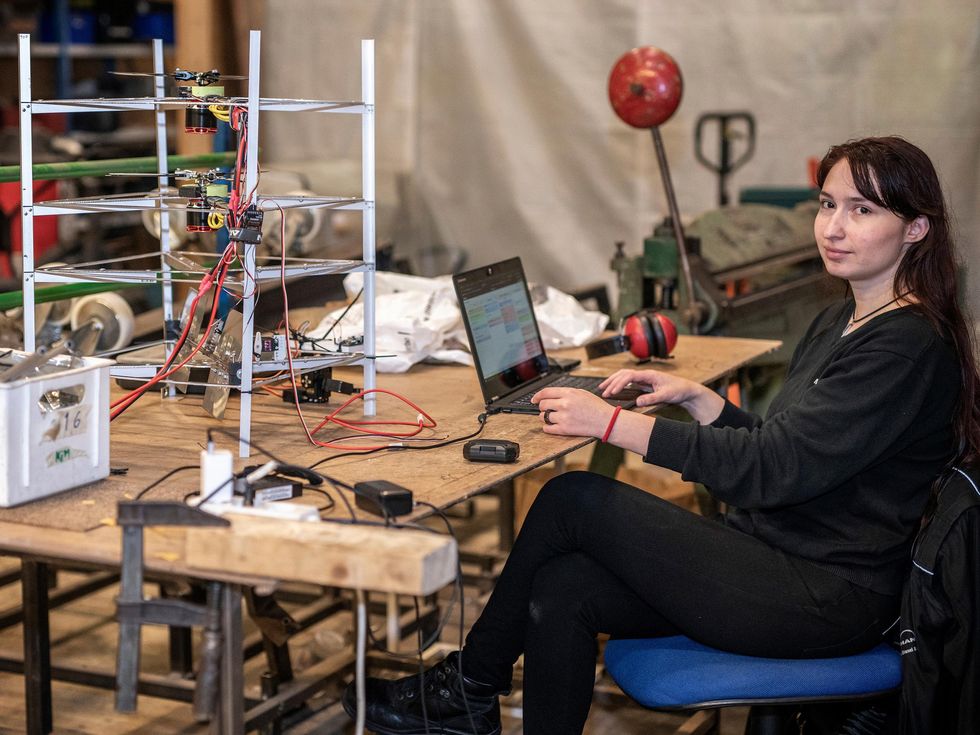

gimbals that swivel the full engine back again and forth to handle the thrust vector. As more aid for our perception that tricky engineering issues can be solved by good and committed men and women, our gimbal system was made and examined by a 21-12 months-old undergraduate pupil from the Netherlands named Jop Nijenhuis, who used the gimbal style as his thesis venture (for which he bought the optimum probable grade).

We are working with the very same guidance, navigation, and handle (GNC) computer systems that we used in the Nexø rockets. A person new problem is the crew capsule as soon as the capsule separates from the rocket, we’ll have to handle every part on its own to bring them both equally back again down to Earth in the wished-for orientation. When separation takes place, the GNC computer systems for the two elements will need to have an understanding of that the parameters for exceptional flight have transformed. But from a computer software stage of perspective, that is a insignificant difficulty in contrast to individuals we’ve solved previously.

Bianca Diana functions on a drone she’s working with to examination a new guidance system for the Spica rocket.Carsten Olsen

My specialty is parachute style. I’ve worked on the ballute, which will inflate at an altitude of 70 km to gradual the crewed capsule through its significant-velocity first descent, and the primary parachutes, which will inflate when the capsule is 4 km over the ocean. We have examined both equally types by acquiring skydivers leap out of planes with the parachutes, most not too long ago in a

2019 examination of the ballute. The pandemic forced us to pause our parachute screening, but we really should resume quickly.

For the parachute that will deploy from the Spica’s booster rocket, the workforce examined a little prototype of a ribbon parachute.Mads Stenfatt

For the drogue parachute that will deploy from the booster rocket, my very first prototype was dependent on a style identified as Supersonic X, which is a parachute that appears relatively like a flying onion and is incredibly easy to make. Even so, I reluctantly switched to ribbon parachutes, which have been much more comprehensively examined in significant-pressure situations and observed to be much more steady and robust. I say “reluctantly” for the reason that I understood how much do the job it would be to assemble these types of a unit. I very first manufactured a 1.24-meter-diameter parachute that had 27 ribbons going across 12 panels, every hooked up in a few places. So on that little prototype, I had to sew 972 connections. A total-scale edition will have seven,920 relationship points. I am hoping to keep an open up mind about this problem, but I also wouldn’t item if more screening displays the Supersonic X style to be enough for our functions.

We have examined two crew capsules in previous missions: the Tycho Brahe in 2011 and the Tycho Deep House in 2012. The following-technology Spica crew capsule will never be roomy, but it will be large sufficient to keep a one astronaut, who will remain seated for the 15 minutes of flight (and for two hrs of preflight checks). The very first spacecraft we’re setting up is a hefty steel “boilerplate” capsule, a fundamental prototype that we’re working with to get there at a functional structure and style. We are going to also use this product to examination hatch style, in general resistance to tension and vacuum, and the aerodynamics and hydrodynamics of the shape, as we want the capsule to splash down into the sea with minimal shock to the astronaut inside. As soon as we’re pleased with the boilerplate style, we’ll make the light-weight flight edition.

Copenhagen Suborbitals at this time has a few astronaut candidates for its very first flight: from still left, Mads Stenfatt, Anna Olsen, and Carsten Olsen. Mads Stenfatt

3 associates of the Copenhagen Suborbitals workforce are at this time candidates to be the astronaut in our very first crewed mission—me, Carsten Olsen, and his daughter, Anna Olsen. We all have an understanding of and settle for the hazards included in flying into area on a selfmade rocket. In our working day-to-working day functions, we astronaut candidates will not get any exclusive remedy or teaching. Our just one further duty hence considerably has been sitting down in the crew capsule’s seat to verify its dimensions. Considering that our very first crewed flight is still a 10 years absent, the applicant list may properly alter. As for me, I assume there is certainly significant glory in just remaining part of the mission and assisting to build the rocket that will bring the very first amateur astronaut into area. Regardless of whether or not I stop up remaining that astronaut, I am going to for good be happy of our achievements.

The astronaut will go to area inside a little crew capsule on the Spica rocket. The astronaut will remain seated for the 15-minute flight (and for the two-hour flight verify before). Carsten Brandt

Folks may surprise how we get by on a shoestring finances of about $one hundred,000 a year—particularly when they understand that half of our income goes to paying rent on our workshop. We keep fees down by getting conventional off-the-shelf elements as much as probable, and when we need customized types, we’re lucky to do the job with companies that give us generous discount rates to aid our venture. We launch from intercontinental waters, so we will not have to pay a launch facility. When we travel to Bornholm for our launches, every volunteer pays his or her own way, and we keep in a athletics club close to the harbor, sleeping on mats on the ground and showering in the shifting rooms. I at times joke that our finances is about just one-tenth what NASA spends on coffee. However it may properly be sufficient to do the career.

We had intended to launch Spica for the very first time in the summer season of 2021, but our plan was delayed by the COVID-19 pandemic, which shut our workshop for several months. Now we’re hoping for a examination launch in the summer season of 2022, when circumstances on the Baltic Sea will be reasonably tame. For this preliminary examination of Spica, we’ll fill the gasoline tanks only partway and will aim to mail the rocket to a peak of close to 30 to fifty km.

If that flight is a good results, in the following examination, Spica will have much more gasoline and soar greater. If the 2022 flight fails, we’ll determine out what went erroneous, take care of the issues, and try out again. It truly is impressive to assume that the Spica astronaut’s eventual 15-minute ride to the stars will be the item of much more than two a long time of do the job. But we know our

supporters are counting down until eventually the historic working day when an amateur astronaut will climb aboard a selfmade rocket and wave goodbye to Earth, ready to take a giant leap for Do-it-yourself-form.

This posting appears in the December 2021 print difficulty as “The To start with Crowdfunded Astronaut.”

A Skydiver Who Sews

HENRIK JORDAHN

Mads Stenfatt very first contacted Copenhagen Suborbitals with some constructive criticism. In 2011, even though hunting at photographs of the Do-it-yourself rocketeers’ most current rocket launch, he had seen a digicam mounted near to the parachute equipment. Stenfatt despatched an email detailing his concern—namely, that a parachute’s strains could easily get tangled close to the digicam. “The response I bought was basically, ‘If you can do better, arrive sign up for us and do it on your own,’ ” he remembers. That’s how he turned a volunteer with the world’s only crowdfunded crewed spaceflight plan.

As an amateur skydiver, Stenfatt understood the fundamental mechanics of parachute packing and deployment. He commenced assisting Copenhagen Suborbitals style and pack parachutes, and a handful of yrs later on he took more than the career of stitching the chutes as properly. He had by no means used a stitching machine before, but he uncovered promptly more than evenings and weekends at his dining home table.

A person of his beloved tasks was the style of a significant-altitude parachute for the Nexø II rocket, released in 2018. Even though doing work on a prototype and puzzling more than the style of the air intakes, he observed himself on a Danish stitching internet site hunting at brassiere elements. He resolved to use bra underwires to stiffen the air intakes and keep them open up, which worked quite properly. Nevertheless he ultimately went in a distinct style way, the episode is a traditional example of the Copenhagen Suborbitals ethos: Gather inspiration and assets from wherever you obtain them to get the career carried out.

Now, Stenfatt serves as guide parachute designer, repeated spokesperson, and astronaut applicant. He also proceeds to skydive in his spare time, with hundreds of jumps to his identify. Owning ample practical experience zooming down through the sky, he is intently curious about what it would truly feel like to go the other way.

From Your Web-site Article content

Similar Article content All around the Internet