A carbon-free foreseeable future will require several thousands and thousands of batteries, the two to drive electric powered motor vehicles and to keep wind and photo voltaic power on the grid. Today’s battery chemistries mostly rely on lithium—a steel that could quickly deal with a world-wide source crunch. Some analysts alert that as EV manufacturing soars, lithium producers won’t be in a position to continue to keep up with need. That could quickly pump the brakes on the world’s clean vitality ambitions, they say.

How big the lithium lack will be, and how substantially turmoil it will induce, is much from particular.

A short while ago, Rystad Vitality projected a “serious lithium source deficit” in 2027 as mining capability lags driving the EV growth. The mismatch could proficiently hold off the manufacturing of around 3.3 million battery-run passenger cars that 12 months, in accordance to the study organization. Without new mining jobs, delays could swell to the equivalent of 20 million cars in 2030. Battery-run buses, vehicles, ships, and grid storage programs will also come to feel the squeeze.

“A big disruption is brewing for electric powered motor vehicle brands,” James Ley, senior vice president of Rystad’s vitality metals group in London, reported in a information release. “Although there is loads of lithium to mine in the ground, the present and planned jobs will not be enough to meet need for the steel.”

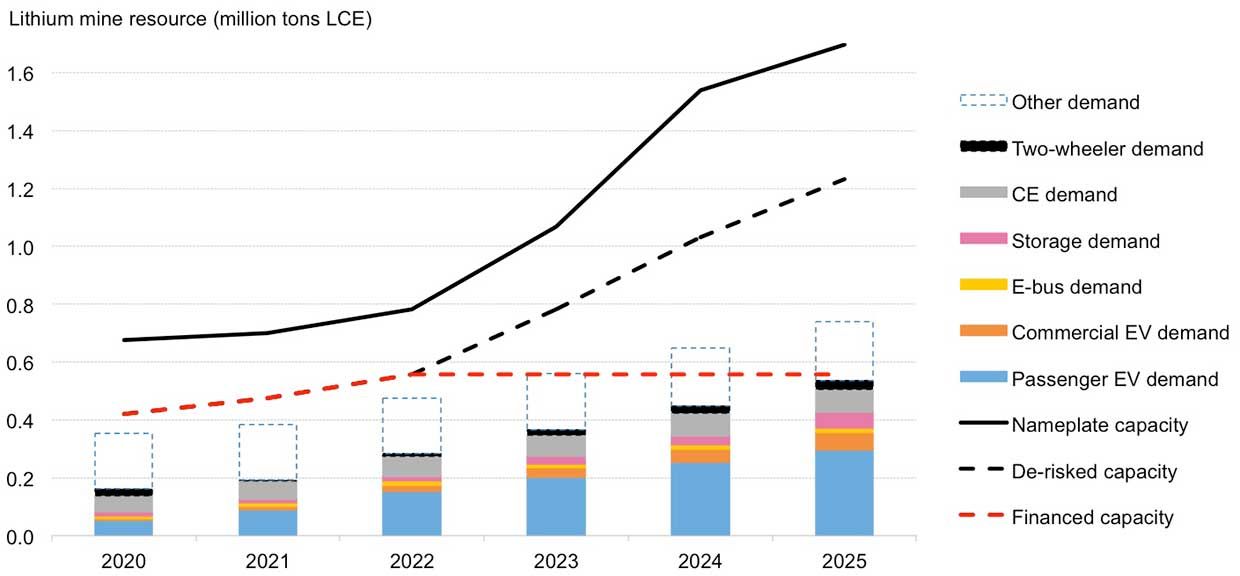

A lithium deficit would flip what is currently a surplus. Demand from customers from battery brands is now about 300,000 metric tons of lithium carbonate equivalent (LCE) per 12 months, although there is 520,000 metric tons of present mining capability for battery markets. Rystad’s assessment exhibits that need from brands could achieve 2.eight million metric tons in 2028. However, mining capability is only anticipated to achieve about 2 million metric tons that 12 months, assuming no new mining jobs are additional to the present-day pipeline.

A globe in which EV assembly lines assemble dust although battery brands scrabble for scraps of lithium is wholly avoidable. But for producers, the resolution isn’t as uncomplicated as mining much more tough rock—called spodumene—or tapping much more underground brine deposits to extract lithium. Which is for the reason that most of the greater, much easier-to-exploit reserves are now spoken for in Australia (for tough rock) and in Chile and Argentina (for brine). To greatly scale capability, producers will also will need to exploit the world’s “marginal” means, which are costlier and much more vitality-intensive to establish than traditional counterparts.

“It’s not that it’s a resource concern. There is no fear that there is not enough lithium to meet need by 2030 or extended,” Sophie Lu, the head of metals and mining for BloombergNEF (BNEF), reported by mobile phone from Sydney. The greater question, she reported, is whether the market can carry on generating lithium at related expenditures as nowadays, although also diversifying source chains absent from today’s dominant geographies and carrying out so without causing environmental injury.

In its latest outlook, printed Wednesday, BNEF reported there are enough lithium jobs in the pipeline to meet need out to the late 2020s—assuming jobs are correctly financed and designed. But a source deficit may well kick in around 2028, Lu reported. Practically $14 billion is however essential to finance the pipeline of lithium manufacturing capability out to 2025, although this pipeline surpasses BNEF’s forecast for need by that 12 months.

Problems about source constraints are driving innovation in the lithium market. A handful of jobs in North The usa and Europe are piloting and tests “direct lithium extraction,” an umbrella time period for technologies that, typically talking, use electricity and chemical processes to isolate and extract concentrated lithium. So-termed DLE could revolutionize the market, akin to how the SX/EW (solvent extraction-electrowinning) process has reworked the copper market, or how electric powered arc furnaces have enabled metal manufacturing making use of electricity instead of coal.

In southwestern Germany, Vulcan Vitality is extracting lithium from geothermal springs that bubble 1000’s of meters beneath the Rhine river. The startup began operating its initially pilot plant in mid-April. Vulcan reported it could be extracting 15,000 metric tons of lithium hydroxide—a compound employed in battery cathodes—per 12 months. In southern California, Managed Thermal Methods is building a geothermal power plant and lithium extraction facility at the Salton Sea. The company reported a pilot facility will start out generating 20,000 metric tons per 12 months of lithium hydroxide, also by 2024.

An additional way to raise lithium provides is to get well the steel from used batteries, of which there is now enough source. Now, less than five p.c of all used lithium-ion batteries are recycled, in massive part for the reason that the packs are tough and high-priced to dismantle. Many batteries now close up in landfills, leaching substances into the atmosphere and losing usable materials. But Lu reported the market is very likely to ramp up recycling following 2028, when the supply deficit kicks in. Developers are now setting up to build new amenities, which include a $a hundred seventy five million plant in Rochester, N.Y. When accomplished, it will be North America’s largest recycling plant for lithium-ion batteries.

Additional into the foreseeable future, even so, the outlook for lithium will get rocky.

Researchers in Finland and Germany a short while ago modeled 18 scenarios for when lithium means might in fact be depleted. They thought of unique assumptions about how substantially lithium is however available in the world’s brines, rocks, oilfields, and other pure features. A state of affairs with “very high” amounts of lithium, or 73 million metric tons, would see lithium totally depleted soon following 2100. Which is if 3 billion EVs hit the road and if the globe will take robust measures to recycle batteries, use motor vehicle-to-grid purposes, and establish 2nd-life battery makes use of.

Lithium availability “will come to be a significant menace to the prolonged-time period sustainability of the transportation sector unless a mix of measures is taken to ameliorate the problem,” the scientists wrote in the 2020 study. This sort of measures contain building new battery chemistries, generating much more synthetic fuels, and creating much more railways—options that don’t require lithium.